The wheel set is an important component of the bridge crane. The layout of the metal structure of the crane is closely related to the diameter and type of the wheel. The wheel set directly determines the overall structure and dimensions of the crane.

The wheel usage of bridge cranes in China and other countries and the maximum allowable wheel pressure of the wheel set were compared, and the calculation results of wheel pressure were compared and analyzed. The results show that the selection of wheel sets can be optimized for design and has good practicability, which can provide references for designers engaged in bridge cranes.

Application of crane wheel sets

At present, for hook bridge cranes with a lifting capacity of less than 50t in China, the mainstream wheel set still adopts the drawings of Dalian Crane Factory, with a corner box structure and paired tapered roller bearings.

Table 1 shows the wheel diameter of various tonnage trolleys of domestic hook bridge cranes below 50t

In the bridge crane market, in addition to the hook bridge crane made in China, there are also many international products, such as Konecranes, Demag, etc. The double-beam bridge crane mainly uses electric hoist as the lifting mechanism, the working level is 2m (M5), and the whole machine can reach A5. This type of double-beam bridge crane products occupy a certain market with its advantages of light weight, small wheel pressure, and stable operation, and have a broad market prospect. The product adopts the integral structure of the end beam and the wheel set, and the wheel bearing is a spherical roller bearing.

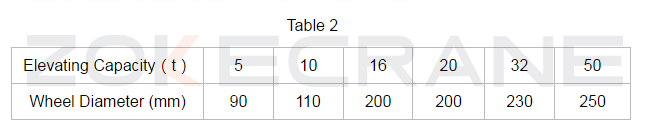

Table 2 shows the wheel diameter of each tonnage trolley of Konecranes

It can be seen from the above two tables that the diameter of crane wheels in other countries is smaller. Compared with the actual height of the end beam where the wheel is located, the reduction can reach 100mm, which can effectively save the height of the plant.

In the design and selection of wheel sets, first determine the allowable wheel pressure for wheels of different diameters. Through data comparison, it is found that the allowable wheel pressure of Chinese-made wheel sets is smaller than that of other countries. The specific wheel pressures are shown in Table 3, Table 4 and Table 5.

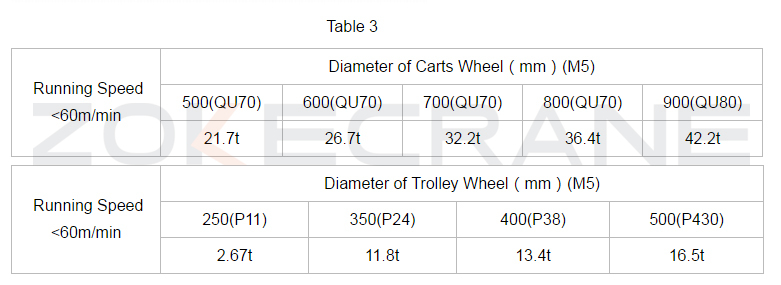

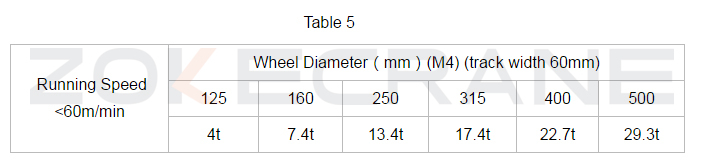

《Crane Design Manual》 can find the allowable wheel pressure of the traditional Chinese hook bridge crane wheel set. Table 3 is an excerpt of the allowable wheel pressure value of each diameter wheel set. Table 4 shows the allowable wheel pressure values of each diameter wheel set of Demag cranes. Table 5 shows the allowable wheel pressure of each diameter wheel set of GH cranes in Spain.

Table 3 Allowable wheel load of wheel set (data from Dalian Crane Factory)

Note: (1) The allowable wheel pressure in the table is the value of the wheel under the corresponding (in parentheses) track. (2) The values in this table are calculated based on wheel materials: ZG310-570, HB320.

Table 4 Allowable wheel load of wheel set (Demag Crane product information)

Table 5 Allowable wheel load of wheel set (Spanish GH crane product information)

From the above three sets of data, it can be found that the allowable wheel pressure of crane wheel sets in other countries is about 30% larger than that in China.

Analysis on the difference of allowable wheel pressure of wheel set

According to the crane design manual and GB/T3811-2008 《Crane Design Specification》, the calculation of the allowable wheel pressure of the wheel set is to calculate the contact strength of the wheel tread. The formula for calculating the allowable wheel pressure of the wheel (line contact) is:

PL=kDlC1C2

Where:

PL—allowable wheel pressure of crane wheels in normal operation, in Newton (N);

k — the allowable contact stress constant related to the wheel material, in units of cattle per square millimeter (N/mm2);

D —The diameter of the wheel tread, in millimeters (mm);

l —The effective contact width between the wheel and the track surface, in millimeters (mm);

C1 —wheel speed coefficient;

C2 —The working level coefficient of the institution where the wheel is located.

It can be known from the formula that the allowable wheel pressure value of the wheel is related to the allowable contact stress constant k under the same working level, the same running speed, the same track, and the same wheel diameter.

The material of domestic crane wheels is mostly ZG340-640 steel, and its tensile strength is 640MPa. It can be found from the design manual that k=5.96. The material of foreign crane wheels is mostly ductile iron GGG70. According to the design manual "When the wheel material is made of ductile iron, the k value is selected as 500N/mm²", so k=5.0.

In this way, for a wheel with a diameter of 500mm, a running speed of 50m/min (C1=1), a working level of M5 (C2=1), and a matching track of QU70, the allowable wheel pressure calculated by the ZG340-640 wheel is: PL =5.96×500×70×1×1=208,600N, which is 21.28t. The allowable wheel pressure of ductile iron wheels is: PL=5×500×70×1×1=175,000N, which is 17.86t.

The values in Table 3 are derived from the ZG310-570 material, and the corresponding k value is 5.42, and the allowable wheel pressure calculated by the formula is 19.36t.

From the above, it can be concluded that the calculated values are all smaller than the data values, and the allowable wheel pressure values of foreign wheel sets have a large difference, and the largest difference is between the cast iron and the cast iron.

Characteristics and methods of wheel set selection and optimization

Reducing the wheel diameter has many advantages for the performance of the whole crane, mainly as follows:

(1) Lower the height of the crane. The construction cost of the steel structure factory building is closely related to the height of the factory building. If the crane's overall height can be reduced through the optimized design of the crane, it is undoubtedly beneficial to save the construction cost of the plant. The wheel diameter directly limits the height of the crane end beam. If the wheel diameter can be reduced, the overall height of the crane can be reduced.

(2) Reduce wheel pressure and reduce plant stress. At present, most of the domestic hook bridge cranes with a lifting capacity of less than 50t use 4 wheel sets. For example, a crane with a lifting weight of 50t and a span of 31.5m uses 4 wheels with a diameter of p800mm, and the maximum wheel pressure can reach 440kN. However, cranes with this tonnage and span generally use 8 small-diameter wheels in foreign countries. In this way, the wheel pressure is dispersed, so that the plant has a better force.

(3) Reduce the model of the drive unit. If the wheel diameter is reduced, the drive torque is reduced, which can reduce the type of reducer in the drive unit and save the cost of the drive unit.

Now our company can design wheels according to the actual situation.If you have any questions, you can contact us, 24 hours professional customer service online to answer you.